Strong combination of STYLE 3D and The knitting factory reducing cost

Strong combination of STYLE 3D and The knitting factory reducing cost and increasing efficiency for sweater industry

Domestic smart design service provider's sweater circle launches 3D R & D services, and provides sweaters, sweater factories, and yarn factories with 3D digital R & D design and online collaboration services. As of now, millions of knitted 3D resources have been deposited, serving nearly 200 Customers, leading the new fashion of intelligent design. The technology behind the scenes comes from STYLE 3D, a 3D digital service platform for the apparel industry, which is independently developed by Lingdi Technology. The strongest 3D digital technology group empowers the industry. The combination of the two provides more efficient and low-cost services for millions of sweater customers.

I am an intelligent design service provider.

Especially proficient in sweater design.

From a yarn, pattern organization, color matching, embroidery, printing ...

Tens of thousands of styles to choose from, massive sweater professional version.

I am the master of the t-shirt design field.

But I also have troubles, customers always complain to me:

The time spent designing each year adds up to more than half of the world.

Proofing fabrics pile up to fill the entire Pacific Ocean.

The materials used for the uniform color stacking can be compared to Mount Everest.

The cost of design trial and error can add up to five small factories.

How to improve efficiency and reduce costs for sweater customers has become something I have been thinking about. After all, the knitting industry is fiercely competitive. As a service platform focusing on knitting fabric design products, I want to stand out in the entire industry and have to find ways to create my own differentiation.

Digital development model

In the process, I came into contact with STYLE 3D, which is a leading domestic 3D digital service platform for the apparel industry, researching knitting simulation in depth, and combining it with production to carry out industrial practices, and has leading technology in the knitting industry.

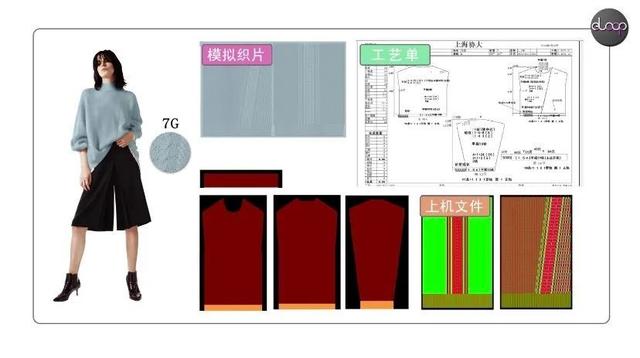

Sweaters, as one of the fabrics, need to be completely simulated by 3D technology due to its complicated changes and detailed textures, which is extremely difficult and requires high technology. And STYLE 3D not only opens the digital link from R & D to manufacturing, but also restores the physical properties of wool fabrics. It helps. From design planning to final sample display, I can provide customers with 3D Compared with their traditional R & D model, the digital presentation method saves time and effort. It is a very meaningful change for the industry.

At the same time, from the design idea to the final presentation of the virtual prototype, I can help customers shorten the development time of a single model from 7-15 days to 2-12 hours, which greatly improves the efficiency of customers.

As a result, customers can develop more sweater fabrics and style designs in the same time, liberating unlimited creativity. While the efficiency is greatly improved, the development cost and time of physical proofing are saved. On the other hand, it also allows customers to see at a glance, clearly understand whether the fabric is suitable for their style design, and at the same time, help the industry to transform and develop in a digital direction.

2. Digital collaboration

Through STYLE 3D, I realized the way for customers to display products in 3d digital form. The flexible simulation of the STYLE 3D platform for fabrics has an unparalleled advantage in the industry. The 3D digital technology not only truly restores the physical effects and physical properties, but also makes the details and texture of the sweater fabric more visible.

Through the STYLE 3D platform, I have realized online sample selection and finalization for our customers. The STYLE 3D platform supports one-click sharing of fabrics through mobile, APP, and computer terminals, setting up a collaborative bridge between customers and their buyers online.

Taking the arrangement effect of the organizational pattern on different collars as an example, I made 3 different arrangement effects for foreign customers. With STYLE 3D, the customer fixed the style online. Customers are very satisfied with this confirmation method.

The customer's approval provided me with a boost for the subsequent large-scale advancement of online collaborative services. Because of this, after the resumption of work, face-to-face communication could not be implemented well, but the services I provided actually helped. Perhaps this is a warning in 2020, marking that digitalization is an inevitable development direction in the future.

3. Digitalization of resource precipitation

In addition, STYLE 3D also supports the precipitation of digital resources. Customers use me to store design materials such as models, patterns and patterns online, which is equivalent to having an online resource library to facilitate the reuse of design materials. At the same time, it also improves its design efficiency.

In recent years, big data and digitalization have gradually dominated and penetrated into various industries. The same is true of the woolen industry. From physical proofing to 3D simulation proofing, from face-to-face communication to online communication, the wool knitting industry is gradually going digital.

Realizing digitalization can greatly improve the overall efficiency of the industry and achieve sustainable development of the industry. With the help of STYLE 3D, the leading domestic 3D digital service platform for the apparel industry, I believe that the sweater industry will be able to realize digital transformation and upgrading as soon as possible, paving the way for the healthy development of the industry.